-

Sinotruk Howo Parts

-

Foton Auto Parts

-

FAW Auto Parts

-

Dongfeng Auto Parts

-

XCMG Spare Parts

-

Yutong Bus Parts

-

Sany Spare Parts

-

Liugong Spare Parts

-

JMC Auto Parts

-

Shacman Spare Parts

-

JAC Auto Parts

-

Shantui Spare Parts

-

Great Wall Spare Parts

-

Lifan Auto Parts

-

Weichai Engine Parts

-

Cummins Engine Parts

-

Gearbox Spare Parts

-

Xiagong Parts

-

Liuqi Chenglong Parts

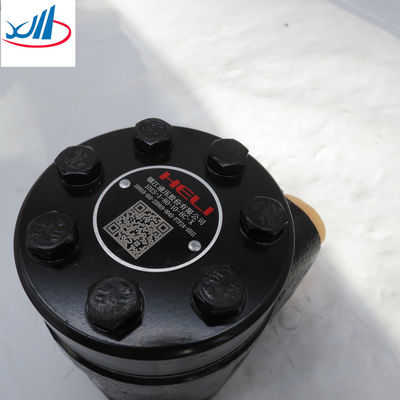

Original Heli 101S-1-80-10-HC hydraulic pump steering machine forklift truck

| Place of Origin | CHINA |

|---|---|

| Brand Name | ORIGINAL |

| Certification | ISO9001 |

| Model Number | 10181-80-10-HC |

| Minimum Order Quantity | 15 PCS |

| Price | USD150 2PCS USD149 20PCS USD148 200PCS |

| Packaging Details | carton |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 2PCS 2 DAYS 20PCS 5DAYS 200PCS 7DAYS |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| NAME | Hot Sale Hydraulic Pressure Pump 10181-80-10-HC | OEM NUMBER | 10181-80-10-HC |

|---|---|---|---|

| SIZE | 3*3*5 | Weight | 0.1KG |

| Packing | CARTON | PAY | Alibaba |

| TIME | 1-13 DAYS | Mode Of Transport | Air Car |

| Material | Iron | MOQ | 15 |

| Highlight | jac high pressure hydraulic pump,lifan Hydraulic pressure pump,10181-80-10-HC Hydraulic pressure pump |

||

| NAME | Original Heli 101S-1-80-10-HC hydraulic pump steering machine forklift truck | |

|---|---|---|

| MOQ | 15 | |

| MATERIAL | iron plastic | |

| OEM NUMBER | 101S1-80-10-HC | |

| SIZE | 3*3*5 | |

| Time | 13 days |

Original Heli 101S-1-80-10-HC hydraulic pump steering machine forklift truck

| Vehicle type | Building loader |

Certification |

ISO9001 |

Warranty period |

1 year | Delivery time | 2 DAYS |

Quality |

original |

Material |

Iron |

| Name |

Original Heli 101S-1-80-10-HC hydraulic pump steering machine forklift truck |

Oem |

101S1-80-10-HC |

| Sea | SHANGHAI NINGBO | Packing |

Carton |

Product display

Original Heli 101S-1-80-10-HC hydraulic pump steering machine forklift truck

| Principle | Principle of forklift steering gear. When the steering shaft of the forklift truck rotates, the force is passed to the nut through the steel ball, and the nut moves axially. At the same time, due to the action of friction, all the steel balls roll between the screw and the nut, forming a "ball flow". After the steel ball travels around the nut for two weeks, it rolls out of the nut and into the pipe, and then flows into the nut through the pipe. Therefore, when the steering gear is working, the two columns of steel balls only circulate in each of their own closed flow channels, but not out. The outer surface of the nut is cut with a rack that is matched with the tooth fan, and the tooth fan is integrated with the shaft of the steering vertical arm. When the nut moves axially through the rack tooth fan, the steering vertical arm shaft rotates. Circulating ball steering gear due to the nut, screw between the rolling friction instead of sliding friction, so the transmission efficiency is high (general spherical worm wheel steering gear transmission rate of 50%-76%, circulating ball transmission efficiency of up to 90%, easy to operate, wear less, and long service life. In the process of forklift steering, the circulating ball steering gear is conducive to the automatic alignment of the steering wheel of forklift, but its recoil force is larger. The forklift wheel is impacted by the road surface, and can be reversely transmitted to the steering wheel, resulting in the appearance of "beater", which is easy to fatigue the forklift driver. For forklifts that often operate indoors or drive on good roads, circulatory ball steering devices are generally used. |

| construction | Forklift steering gear construction. It is mainly composed of lower cover, gasket, shell, steel ball, square nut, pipe, bearing seat, upper cover, steering screw, adjusting screw, adjusting gasket, bearing, tooth fan, steering vertical arm shaft, and by two moving pairs, one is screw, nut, the other is rack, tooth fan and other forklift accessories. A semi-circular spiral groove with end face is processed on both the steering screw and the nut, and the spiral channel with circular section is formed. There is a hole on the side of the nut, and the steel ball is inserted through the hole, so that the two pipes and the bolt-shaped channel in the nut form two separate closed steel ball "flow channels. |

![]()

![]()

![]()

![]()

![]()

The steering system configured on the car can be roughly divided into four categories: (1) mechanical steering gear; (2) mechanical hydraulic power steering system; (3) One is the electronic hydraulic power steering system; (4) Another electric power steering system.

Classification introduction

Mechanical steering system

Mechanical steering gear is widely used. According to their different structural characteristics, it can be divided into rack and pinion steering gear, circulating ball steering gear, worm roller steering gear and worm finger pin steering gear.

Rack and pinion type

Rack and pinion steering gear is composed of a steering gear integrated with a steering shaft and a rack usually integrated with a steering cross tie rod. Compared with other types of steering gear, the main advantages of rack and pinion steering gear are: simple structure and compact; The shell is made of aluminum alloy or magnesium alloy die-casting, and the mass of the steering gear is relatively small. Transmission efficiency up to 90%; When there is a gap between the gear and the rack due to wear, the spring installed on the back of the rack, near the active pinion can be adjusted to automatically eliminate the gap between the teeth, which can not only improve the stiffness of the steering system, but also prevent the impact and noise during work; Small volume occupied by the steering gear; There is no steering rocker arm and straight tie rod, so the steering wheel Angle can be increased; Low manufacturing cost.

The main disadvantages of rack and pinion steering gear are:

Due to the high reverse efficiency (60% ~ 70%), when the car is driving on the uneven road surface, most of the impact force between the steering wheel and the road surface can be transmitted to the steering disk, which is called recoil. The recoil phenomenon will make the driver nervous, and it is difficult to accurately control the direction of the car, and the sudden rotation of the steering disk will cause a beater, causing injury to the driver.

According to the position of the input gear and the characteristics of the output, the rack and pinion steering gear has four forms: the middle input, the output at both ends; Side input, output at both ends; Side input, middle output; Side input, end output.

When side input and middle output are adopted, the left and right tie rods fixed with the rack extend to near the longitudinal symmetric plane of the car. As the length of the tie rod increases, the swing Angle of the tie rod decreases when the wheel is running up and down, which is conducive to reducing the motion interference between the steering system and the suspension system when the wheel is running up and down. The tie rod and the rack are bolted, so that the two tie rods and the rack move to the left or right at the same time, so that the steering gear housing is provided with a long slot in the axial direction, thereby reducing its strength.

When the two-end output scheme is adopted, it is easy to interfere with the steering mechanism of the suspension system because the length of the steering rod is limited.

Rack-and-pinion steering gear with side input and one end output is commonly used on the first minivan.

If the rack and pinion steering gear is engaged with the straight gear, the smoothness of operation is reduced, the impact is large, and the working noise is increased. In addition, the Angle between the axis of the gear and the axis of the rack can only be a right Angle, which is eliminated because it is not suitable for the overall arrangement. The pinion and rack steering gear with helical cylindrical gear and helical rack meshing is used to increase the contact degree, run smoothly, reduce the impact and working noise, and the Angle between the gear axis and rack axis is easy to meet the requirements of the overall design.

The rack section shape has three types: round, V-shaped and Y-shaped. The manufacturing process of circular section rack is relatively simple. Compared with the circular section, the V-shaped and Y-shaped section rack consumes less material, saving about 20%, so the quality is small; The two bevel planes located below the teeth are in contact with the rack bracket, which can be used to prevent the rack from rotating around the axis; The tooth width of the Y-shaped section rack can be made wider, so the strength is increased; A gasket made of antifriction material (such as teflon) is usually installed between the rack and the bracket to reduce sliding friction.

According to the different positions of the rack and pinion steering gear and the steering trapezoid relative to the front axle, the rack and pinion steering gear has four layout forms on the automobile: the steering gear is located behind the front axle, and the rear trapezoid; The steering gear is located behind the front axle, and the front trapezoid; The steering gear is located in front of the front axle, and the rear is trapezoidal; The steering gear is located in front of the front axle, with the front trapezoid.

Rack and pinion steering gear is widely used in micro, ordinary, intermediate and middle premium cars, and even in premium cars. Some lorries and buses with small loads and independent suspension front wheels also use rack-and-pinion steering gear.